Jigging Machine

⚙️ Jigging Machine – Precision Separation for Maximum Efficiency!

Smart Separation. Superior Recovery. Engineered for Performance.

Industries We Serve:

🛠️ Manufacturing | 🏗️ Construction | ⚙️ Engineering | 🚜 Agriculture | 🏭 Heavy Equipment

Choose our Jigging Machine for a smarter, cleaner, and more efficient mineral processing solution.

Boost Your Yield, Reduce Waste – Invest in the Right Separation Technology

Applications of Jigging.

Jigging is particularly effective in processing ores with a significant difference in particle density. Common applications include:

- Iron Ore: Beneficiation of low-grade iron ore by removing impurities.

- Manganese jigging

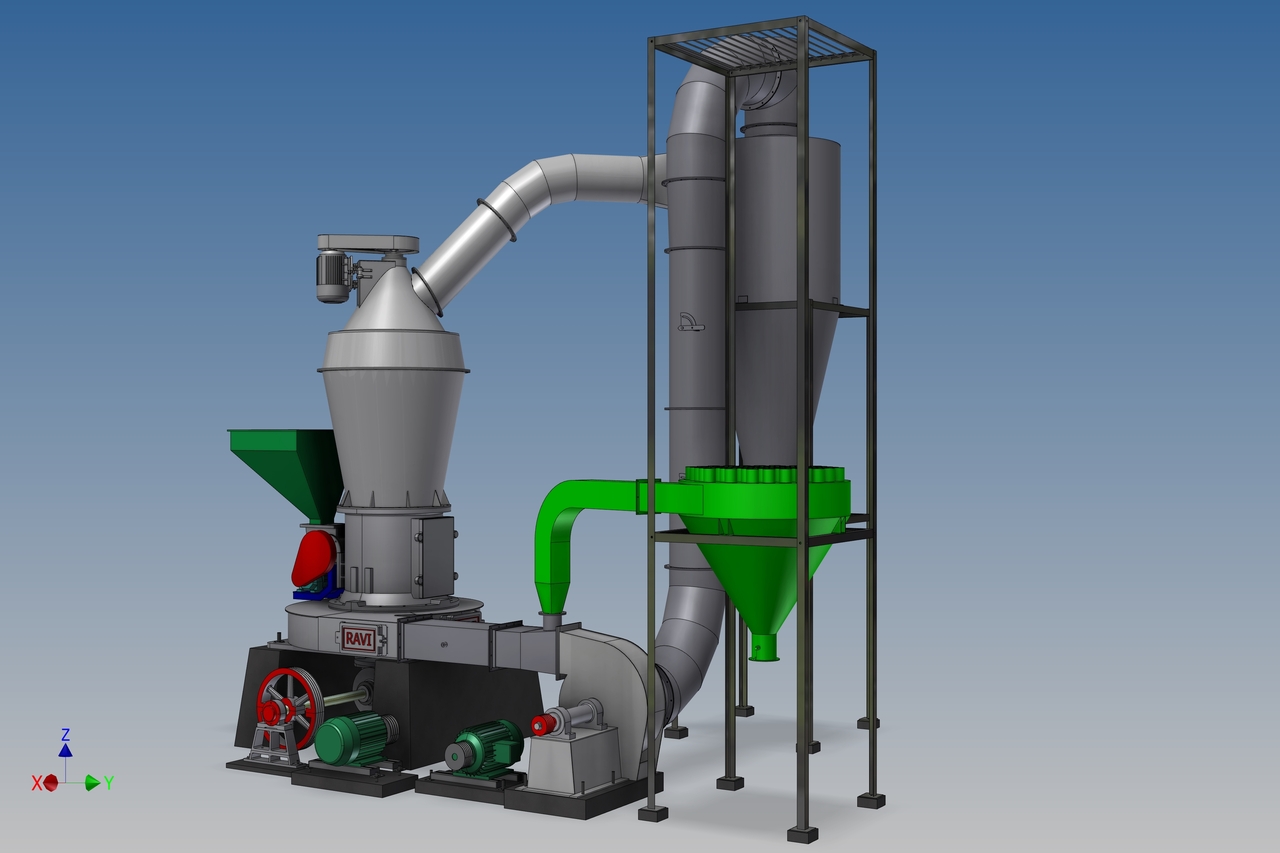

HOW JIGGING WORKS

- Preparation: The ore is first crushed and ground to achieve a suitable particle size, typically ranging from 0.2 mm to 50 mm, depending on the specific requirements of the jigging process.

- Pulsation: The prepared ore is introduced into a jig bed, which is subjected to a vertical pulsating water flow. This pulsation causes the particles to move and stratify based on their density.

- Stratification: During the upward pulsation, lighter particles are carried to the top, while heavier particles sink to the bottom. This results in a layered arrangement of particles within the jig bed.

- Separation: The stratified particles are then separated: the denser materials, often the desired mineral concentrates, are collected from the bottom, while the lighter gangue materials are removed from the top as tailings.

HOW JIGGING WORKS

Why Choose Us Our Jigging Machine ?

✅ Advanced Gravity-Based Separation – Ideal for heavy mineral concentration

✅ Robust Construction – Built to withstand continuous operation

✅ Energy-Efficient Design – Low power consumption with high output

✅Adjustable Pulsation Settings – For optimized separation of various materials

✅User-Friendly Operation – Simple controls, easy maintenance